The Benefits of Electric Drives in Downhole Equipment

Every oil and gas extraction operation now includes gathering big data and managing the down-hole processes, from surveying and preparing extraction areas to maximising and optimising the production of mature oil and gas wells.

Over the years, the oil and gas extraction sector has maintained the same objectives: maximise output to satisfy the energy needs of the market while doing it effectively, affordably, and sustainably. Efficiency and sustainability are becoming a more prominent role as the sector sets its sights on achieving zero nett carbon emissions. Even though it has significant technological and environmental obstacles, downhole drilling has the greatest potential for technological advancement. To achieve these goals, industry mindsets must change to embrace a more data-driven strategy, which is driving downhole drilling towards electrification.

Electric drive benefits

The concept of electrifying downhole operations is not new, but advancement has lagged over time as a result of a combination of overcoming the extremely challenging climatic conditions, a lack of cutting-edge technology, and resistance to change. Technical advancements in motor, electronics, and battery technologies are providing the tools needed to move towards the electrification of the oil and gas industry, however, since old solutions like hydraulics are no longer cost viable in fulfilling the new targets set by the industry. There are key advantages of an all-electric system as well.

Efficiency gains are made possible by digitisation. Operators can make better and more consistent strategic production control decisions when they have access to a real-time data reservoir and precise control positioning. For the administration of manufacturing activities in the future, both onshore and offshore, digitalisation is becoming more and more crucial. Large volumes of data, including information on reservoir behaviour, production procedures, well integrity and safety, and the health and operation of the equipment, may be gathered in real time using electric production systems. With this digital strategy, a project’s overall efficiency and safety are increased, and its carbon impact is decreased.

Electric infrastructure construction is far more affordable and simpler to maintain. In comparison to hydraulics, an electric wire may be extended further, and a single line can be used to control various systems and provide sensor input. This enables creating and maintaining infrastructure with numerous branches and expansions easier. Additionally, the leakage danger associated with hydraulic lines is fully eliminated by an electric connection. Battery technology advancements have also made it possible to use batteries in harsh environments.

Electric motors allow for precise and quick control when used for valve actuation and control. Electric drive inputs and commands are received in real-time and are immediately carried out, allowing operators to quickly adjust and immediately optimise their operation. Electric motors can be controlled using a variety of factors, including torque (by measuring the motor’s current), speed and position (using motor halls or resolvers), and possibly other parameters depending on the sensors used. Full motor control is made possible as well as the opportunity to gather data that may be utilised to forecast the state of the motor health condition.

Technical challenges and solutions

Extreme environmental conditions have been a significant barrier to using electric drives more frequently in downhole operations. Components of conventional electric motors cannot survive downhole temperatures, which frequently exceed +200°C, high pressures, and potentially significant shocks and vibrations. Motors must run consistently, increase the lifetime of a downhole tool, and require less maintenance in order to meet specified cost efficiency targets and prevent expensive downtime. In order to achieve the industry’s goals of increased productivity and efficiency, it is essential to maximise the output of already-existing wells while simultaneously drilling into harder, unconventional wells and pushing electric motor technology even further.

As conventional motors are not suitable for these industry demands, custom solutions tailored to downhole specifications needed to be developed. To do this, successful motor manufacturers must have the expertise and resources to perform all the development steps, plus ensure reliable production and testing processes. Designing such drive system requires specialized knowledge in material behavior at extreme temperatures as well as extensive testing to make sure all components can survive the HPHT (high pressure, high temperature) environment found in downhole operations.

Conventional permanent magnet DC motors typically use neodymium magnets which start to demagnetize once temperatures of +150°C are exceeded. Similarly, conventional winding insulations are not able to withstand the extreme conditions. It is important to keep in mind that temperature ratings include ambient, and the added temperature caused by the load. That means a certain safety margin needs to be considered as the motor must be able to operate under load without overheating. Other motor parts must be made of high-grade stainless steel and the use of adhesives or plastics should be avoided.

The process of development includes more steps than just selecting the appropriate components. In order to validate that the correct design has been implemented and that the motor can deliver the requisite life-time in these harsh conditions, it is also necessary to specify and carry out acceptable environmental tests. To achieve reliable manufacturing, production processes must be developed and include appropriate testing both during production and during final inspection.

The maxon solution

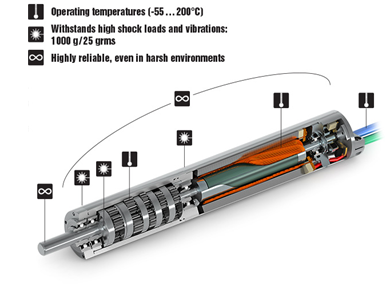

maxon’s heavy-duty platform portfolio provides the robust design that is critical for extreme operating conditions. For example, their EC 22 HD brushless DC motor with GP 22 HD planetary gearhead provides:

- An Ultra compact (Ø22 mm), highly efficient

(>75 %) and powerful (240 W) drive solution - A fully welded stainless-steel assembly along with encapsulated samarium-cobalt magnet

- A high temperature ironless core winding, proven to withstand temperatures up to 240° C

- A gearhead designed for high torque (12 Nm overload torque capability)

Along with these technical capabilities, these motors incorporate new materials and process technologies. An ironless core winding and high-performance rotor is the “heart” of maxon heavy duty motors. Together with the powerful gearhead, maxon provides high torque drive solutions. Most parts of heavy-duty drives are made of stainless steel. The assembly minimizes the use of adhesives, concentrating instead on the connection of individual components through mechanical fits and secured with laser welding. This results in a reliable and mechanically robust drive system.

Some key advantages of maxon HD motors include:

- Wide temperature range

(-50 to 200°C) components tested up to 240°C - Robust design laser welded connections

- High performance to volume ratio, compact, high-power density

- Low energy consumption, high efficiency

- Excellent control properties, linear motor characteristics

- Operation in air or in hydraulic oil

- Low magnetic interference

- High quality/reliability production process controls

Qualification and production testing

To ensure that motors can withstand harsh downhole conditions, it is important to define and conduct proper tests during the design qualification phase as well as during serial production. Manufacturers must have enough resources and expertise to develop and conduct these tests and implement all the necessary steps on the production line to ensure that each unit produced meets the requirements. There are three specific tests that are required to assure the long life and proper operation of these motors.

To ensure that motors can withstand harsh downhole conditions, it is important to define and conduct proper tests during the design qualification phase as well as during serial production. Manufacturers must have enough resources and expertise to develop and conduct these tests and implement all the necessary steps on the production line to ensure that each unit produced meets the requirements. There are three specific tests that are required to assure the long life and proper operation of these motors.

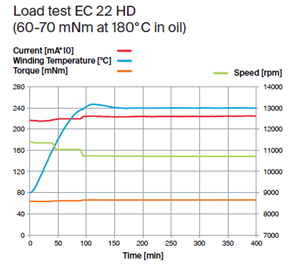

Internal full load test

Motors are tested in air or in hydraulic oil at extreme temperatures and under full load during continuous operation. During this load test the winding heats up to its maximum rated temperature. Continuous monitoring provides information on the drive’s performance characteristics.

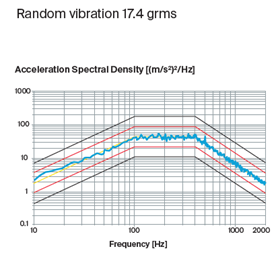

Vibration and thermal stress test

Drives are placed in a climate-controlled enclosure and subjected to high vibration. Testing is carried out with the motors in operation at high temperature. The motors are required to continue functioning within their performance specification while vibrations are applied in all directions.

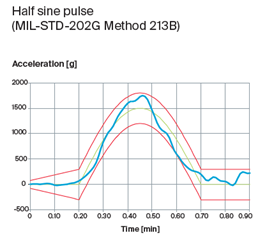

Shock test

The laboratory system performs a variety of shock loads of more than 1,000 G. After the shock test, the drives must be fully functional.

Standard test procedures are also performed prior to delivery to the customer. All of maxon’s HD drives the motor plus accessories must pass these procedures, which include:

- Environmental Stress Screening (ESS)

o high temperature test

o load test

- General Electrical Test

o insulation test

o maxon standard test

- Visual and Dimensional Check

o visual inspection

o dimension checks

Application examples

A typical use for electric motors in downhole operations is in Measurement While Drilling (MWD) systems, which use electric actuators in their mud pulser units. This equipment is responsible for using the complex technology that provides a second-by-second feed on the progress of the bore. Because the data transferred to the drilling technicians is critical to the operation—allowing them to respond quickly to make drilling corrections—the motor used in the actuator must provide power efficiency, reliability, and robustness.

Battery technology developments have increased the use of electric motors in downhole operations where they can also be used as generators to power the batteries. For this to happen, the motors must be very efficient. Brushless HD motors from maxon are not only suitable for the extreme environments attributed to downhole operations they can be used as DC or AC voltage generators using the drilling fluids pumped downhole. A voltage rectifier is required for DC voltage production, while AC voltage can be acquired using two of the three motor phases. The basic calculations are very simple due to the linear behavior of motors with slotless windings.

Another emerging use for electric actuators is in intelligent flow control valves. Instead of switching between fully open or closed positions, electric motors allow for highly precise control of flow valves to achieve optimal flow rate at any time. Software development has provided easy monitoring and control via user friendly interfaces at the surface. For example, it has been shown that smart gas lift systems have the potential to reduce lifting costs significantly, plus increase the well production capabilities with less intervention.

Well inspection is another segment with large potential for using electric actuators to achieve more efficient operation. Whether actuating a wheel assembly to drive a conveyor or controlling fingers of a multi-finger imaging tool to inspect the casing, electric drives are a great choice for increasing operational speed and precision. High precision positioning linear movements can be made by incorporating linear actuators with ball screws integrated into the gearhead and a heavy-duty resolver at the back of the motor. Overall, electric motors can solve challenges in various downhole tools, from drilling operations to completion and well inspection.

Conclusion

The oil and gas sector will undergo a great deal of change and innovation in the coming years and decades in order to satisfy strategic targets like providing affordable, carbon-free energy. These advances and modifications may be fueled by the development of all-electric systems. It is anticipated that an oil and gas extraction project will electrify all of its components, including the downhole portion. Many applications are actually migrating from more conventional technologies like hydraulics to electric actuation right now. With the industry facing difficult targets it is thrilling to see where the road leads and what kinds of innovations emerge in the future.

For information:

maxon motor Australia tel. +61 2 9457 7477.

A light-weight exoskeleton for the elderly.

Graduate students at the National Taiwan Normal University (NTNU) have developed an improved exoskeleton design using maxon brushless DC motors and motor controllers.

Members of the Mechatronic Engineering department of NTNU have developed a lightweight lower extremity exoskeletal robot to assist people who have difficulty walking. The exoskeleton provides support for the hips and knees.

Exoskeletons have been in development since the mid-seventies and have continued to evolve following advancements with technology. Price, weight, safety, ease-of-use, and a proper fit all pose challenges to developing exoskeletons that are practical for the general public.

Graduate students in the Intelligent Automation/Robotic Lab at NTNU found that—due to heavy motors and batteries—most exoskeletons are difficult for users to put on without assistance. The lack of a user-friendly design means that most exoskeletons are inconvenient and can pose a safety risk to the user. Due to the high cost of hardware, they’re also expensive.

Using maxon DC brushless motors and motor controllers for the hip and knee joints, the students were able to develop a high-torque wearable unit that is smaller and lighter. By incorporating lightweight 3D printed components along with high-efficiency DC motors from maxon, the exoskeleton provides an agile, user-friendly solution to an aging population.

The team’s next goal is to extend the development an exoskeleton for the ankle joints and feet, exploiting the same easy-to-wear design as their exoskeleton for the hips and knees.

maxon motor Australia tel. +61 2 9457 7477.

maxon’s driven magazine is out now!

The latest edition of driven brings you interesting reports, interviews, and news from the world of DC motor and drive technology.

driven magazine from maxon is now available online and can also be ordered in print, free of charge. The magazine is published in three languages.

Which brushless DC motor to choose?

The technical article in the current issue of driven gives engineers an excellent overview of the various brushless DC motors made by maxon and their properties. All beautifully summarised using graphics. Least but not least, readers are transported to Great Britain and the gear motor specialist Parvalux. The long-established company joined the maxon Group in 2018. What has changed since then? And what synergies can be used in future?

Robot on four legs

Wherever it goes, it is sure to attract attention. The red walking robot ANYmal provokes a reaction, which is why it also made it to the cover of the maxon magazine driven – representing the ever-increasing number of inspection robots worldwide.

Climbing, crawling, walking, or flying: inspection robots can be found everywhere, whether in sewer systems, on wind turbines, or at the bottom of the ocean. And their numbers are expected to increase dramatically in coming years. This is because they do work that is either too monotonous or too dangerous for humans. One of the most well-known of their ranks is the red walking robot ANYmal developed by Zürich-based start-up ANYbotics. The editorial staff of driven magazine took a look behind the scenes and found out from the engineers how they taught their “baby” to walk.

BIKEDRIVE – the electric bike system

For readers who prefer two wheels to four legs, we have an interesting report about the new electric bike system BIKEDRIVE AIR. It makes it possible to design and produce lightweight electric sports bikes – for the mountain or the road. They provide a natural cycling experience and represent an alternative to electric bikes, which are increasing in weight and power.

For more information contact maxon motor Australia tel. +61 2 9457 7477.

Fully automated drone powered by solar energy

XSun designs and manufactures a drone that is both energy-independent and can make its own decisions, for fully-automated missions. The company needed reliable, high-performance sub-assemblies to design it’s SolarXOne. The start-up approached maxon for the propulsion system.

Adapting space technologies for use at lower altitude was the idea behind creating a fully automated solar powered drone. Benjamin David started his company XSun, and with a decade of experience at Airbus Defense & Space his idea produced SolarXOne: A solar-powered, electrical, self-contained drone with a tandem wing design.

SolarXOne, with its dragonfly-like design, has excellent aerodynamic performance and a large surface area of solar panels, to collect as much solar energy as possible. This is all within a very high-performance, fully-electric environment.

“We firmly believe that a combination of new technologies and renewable energy sources will best meet current environmental, economic and societal challenges,” says Benjamin David. He also points out that solar power increases the on-board battery life by a factor of 3.

Just like a satellite, SolarXOne is packed with technologies. Half airplane, half drone, this UAV weighs 25 kgs and has a 4.50 metre wingspan. With a daily flight range of 600 km it can fly over thousands of acres, producing image resolution within centimetres of accuracy. Many industries could benefit from the drone for a wide variety of missions:

- Mapping and topography of large areas on land or at sea, such as natural bush reserves

- Very high-resolution photographic surveys for large-scale linear infrastructure (pipelines, electricity lines, roads, rivers, etc.)

- Photographic surveys for precision agriculture, for example forest mapping

- Monitoring and inspection missions.

maxon motors are “definitely the best”

The guiding principles of the SolarXOne design was a DC motor system that was efficient, top quality, reliable and durable. “Because of the fully electric design, we had to strive for cost and energy efficiency in every assembly. This is why it was essential to work only with the best, and that means maxon for the propulsion system,” said David. For propulsion, the challenge was to find the most reliable, highest performance, and smallest systems possible, with virtually the same requirements as in the aerospace sector. “In those three areas, maxon is definitely the best. There are very good reasons why they supply NASA with its robot motors! We were delighted to see maxon enter the drone market, and our collaboration was set up very quickly,” adds David.

Every aspect of the technology had to be pushed right to the limit for the drone to be able to fly independently for more than 12 hours. XSun took advantage of maxon’s expertise in controllers, DC motors and propulsion.

“From an energy point of view, the aim was to keep consumption as low as possible while remaining as light as possible: a genuine technological challenge”, recalls Michael Niemaz, Aerospace Project Engineer at maxon, who has been working with XSun since 2019. Back then, maxon had just released its first drone motor range. To meet XSun’s requirements, maxon adapted one of its brushless drone motors, the ECX 87 Flat DC motor.

Luise Löskow, Aeronautics Project Manager at maxon, says: “When we started working with XSun, the design of this type of DC motor only existed in its basic form. This is why we had to customise a product that was still under development, to which we had to incorporate new features such as sensors. Our experienced team (design engineers, test engineers, quality engineers, purchasers and production operatives), had in-depth discussions about the various technical requirements and problems, so as to find appropriate solutions. Finally, we increased the power of the ECX87 Flat DC motor and modified its winding for optimum propulsion. SolarXOne is now equipped with two adapted ECX87 Flat DC motors positioned at the front of the aircraft.”

“For SolarXOne to be able to fly over cities in total safety, XSun wanted to have its drone certified as far as possible. This where maxon’s expertise played an important role, because we provide a build quality that guarantees a sufficiently reliable DC motor to be certifiable in the future,” Michael Niemaz pointed out. The founder of XSun agrees with this, adding: “It would have been hard to achieve the same level of quality with a partner other than maxon. Very few companies would be able to provide a highly detailed 25-page test report!”

Ever since they met at the Paris Air Show in 2019, the maxon and XSun teams have been working in close collaboration. In July 2020, for its first long-range solar flight, the SolarXOne succeeded in flying silently for 12 hours without any CO2 emissions, and completely independently. Since then, it has completed operational assignments for various clients in France and other parts of Europe.

For more information, visit: XSun.fr

maxon motor Australia tel. +61 2 9457 7477.

Brushed DC motors for higher temperatures.

DC motors that withstand high temperatures up to 200⁰C were exclusively the domain of brushless DC motors. maxon has now changed that with the new HT (High Temperature) brushed DC motor.

Motors capable of operating at high ambient temperatures are nothing new to maxon. The HD (Heavy Duty) brushless DC motor range, developed to operate in ambient temperatures up to 200⁰C, has been on the market for over a decade. Until now, these temperatures were exclusively the domain of brushless motors; maxon has now changed that with the new HT (High Temperature) brushed DC motor.

A major oil and gas company approached maxon looking for a brushed DC motor capable of operating in ambient temperatures up to 180⁰C. Their established multi-imaging tool, utilised for pipework casing inspection, used a high temperature brushed DC motor. However, when new tools with higher seismic shock levels were added, the current DC motor system failed as it wasn’t robust enough. Unsurprisingly the company didn’t want to redesign the entire system as this would be expensive and time-consuming; instead, they turned to maxon to provide a solution. maxon’s engineers set about developing a tailored DC motor drive system based on the standard DCX 22mm brushed DC motor series for the downhole application.

The main fundamental parts of the DC motor, namely the winding and magnet, were the first to be dissected. Unlike the HD brushless DC motors that use Samarium Cobalt (SmCo) magnets for high temperatures, the engineers elected to use a new high-temperature grade Neodymium (NdFeB) magnet. The reason being: strength. Samarium Cobalt magnets capable of elevated temperatures have been available for several years, but they are not as strong as Neodymium magnets. As well as being slightly weaker, using Samarium Cobalt magnets would mean the size of the DC motor would have had to increase to meet the torque requirements.

High-temperature windings are not new to maxon. The maxon configurable DCX motor series using standard winding operates to a recommended maximum of 125⁰C. If the temperature increased above this level, the insulation in the winding would become soft and unstable and could collapse onto the magnet. So maxon’s engineers created a customised winding and produced some samples. Once this was validated, the electro-magnetic circuit was complete.

A DC motor is much more than just the magnet and winding, so once a viable design for these was complete, the engineers looked at the rest of the motor to ensure all the other elements were capable of enduring the temperatures. The standard polymer brush cover required a new design using high-temperature capable material.

maxon produced the first samples and then came the validation testing. maxon’s test laboratory facilitates extensive environmental testing. The motors were heated up to 180⁰C in the test chamber and then run. Also, the stability of the rotor was tested at 180⁰C and 200⁰C. Once the maxon engineers were happy that the solution would work in the application, they supplied the customer with samples for their testing. These passed with no issues, and the motors released to production standards.

The DCX22S HT DC motor works with the GPX22 and GPX26 gearbox ranges, including the high-efficiency gearbox GPX22UP. These can have extended temperature lubrication to match the motors ambient temperature capability. Your local maxon sales engineer will help you match the motor and gearbox combination to your application.

maxon Group Australia tel. +61 2 9457 7477.

Australian company develops world’s smallest Robotic Arms and Gripper for Harsh Environments.

Australian company Blueprint Laboratories combine mechatronic engineering and their passion for surfing and diving for their latest innovation – the world’s smallest ROV manipulator that operate in the harsh environment of the ocean floor.

In the following article we discuss how one company employs creative design techniques and online configuration tools to provide customised motors and gearheads for their latest robotic arm and gripper – able to fit into a wide variety of applications.

The CEO of Blueprint Lab, Paul Phillips has combined his passion for mechatronic engineering with his love of surfing and diving in the ocean. The company, located in the Sydney, Australia, designs and manufactures products that operate in the harsh environment of the ocean floor. According to Paul, “I realised at an early stage that subsea vehicle manufacturers were in need of specialised hardware for performing remote manipulation tasks. Developing such tools themselves was prohibitively expensive and complex. The Blueprint Lab team “love tech more than anything else” which is why we are intent on inventing technically innovative products. We love what we do,” he explains.

The unique selling point of the company’s robotic manipulators and grippers is size. The Reach Alpha 5 is the world’s smallest ROV manipulator, according to Paul. When curled up, it’s only 23x15x4cm and is approximately 58cm at full extension with a dynamic reach of 40cm. The arm is able to lift 2kg of weight at full reach and an axial load rating of 100kg. End-effector closing force is about 600N. The units are designed to operate at depths of up to 300 meters.

As a usable addition to any ROV, the Reach Alpha 5 is an all-electric device that runs off of 18-30 V DC motor. The system is fast and easy to integrate through standard RS232/RS485 protocols. The unit offers leak detection for peace of mind prior to vehicle launch. Interchangeable end-effectors include standard pincer grips as well as quad jaws, specialised recovery jaws, needle nose grippers, soft jaws, parallel jaws, and rope cutter jaws. The units are primarily made of hard anodised AL6061aluminum. Both arms and end-effectors can be made from stainless steel for harsher environments and where increased strength is needed.

The Reach Alpha 5 is driven by maxon DCX 16mm DC motors and planetary gearboxes. The motors are integrated in a side-by-side arrangement so that they are able to drive in both directions efficiently. An in-house designed controller fits between the motors to maintain a compact arrangement. A spiroidal gearbox assembly, also designed in-house, is used as the final drive element. Feedback for the system is supplied by a built-in hall-effect absolute position encoder. “For the higher torque joints, we use high-torque gearboxes due to their increased load capacity. For other joints, such as the grabber and the inline rotation motors, the standard DCX components were sufficient,” Paul said.

“Because we developed the hardware, firmware, and software for our products in-house, we were able to deliver much higher levels of optimisation, serviceability, and support to our customers,” Paul said. The biggest challenge for the company has been taking a product from the prototype to production stage of development. The need to get everything perfect every time is essential in order to provide the conformance, process capability, and repeatability in production that customers require. Because of this, Blueprint Lab sees one of maxon’s major advantages is their online configurator for customising DC motors—with production in 11 days—which allows customers to order motors 24/7. And then deliver the product in production level quantities as the market demands.

The maxon DCX program includes motors that offer high power density, high efficiency and are a smooth-running line of motors. The motors are available for online configuration in sizes from 6mm to 35mm. Customers can choose between precious metal or graphite brushes, ball or sintered bearings, and much more in a contained or frameless package. maxon allows users to configure and combine DC or brushless DC motors and planetary gearheads and sensors according to their individual specifications. Through the different generations of the product the DC motor and gear ratio changed to better meet customer requirements and improve robustness. According to Paul, “The DCX range allowed for these changes to be seamless without requiring any mechanical design”.

During the development stage for an actuator, for example, the company might order as many as 20 motor variations online before settling on the right product. This actually saves the company money, since research time is so much more expensive. Plus, it allows Blueprint to test all available options prior to selection.

During a brainstorming session with maxon’s Board of Director and Head of Internal Audit, Dr Bianca Braun and Australian Managing Director, Brett Motum, additional ideas were offered. During the session, Paul and his team turned to maxon controllers as a subject. One initial desire for the company would be to incorporate a stripped-down version of maxon’s ESCON servo amplifier to suit motor diameters. The conversation further drifted into methods where a controller could be configured by an engineer. The designer would select from features already resident in the motor controller hardware and then configure the shape of the controller online. “maxon’s openness to new ideas is important,” Paul said.

Most applications for the company’s robotic manipulators are in hard to reach or dangerous locations. Units are used on ROVs for search and recovery operations, conducting offshore infrastructure inspection for oil and gas operations, collecting samples for marine science research, as well as in Special Recovery Operations by the military and civil first responders. Besides operating under the ocean for research, the Reach Alpha 5 can be used for police and military operations such as bomb disposal robots and for close visual inspecting in petrochemical and nuclear operations.

The build-up of core technologies in-house for the Reach Alpha 5 provides Blueprint Lab with a strong technical advantage over other companies while they expand into broader markets, such as nuclear, petrochemical, land, and aerospace applications. “We are always thinking of the next developments,” Paul explained. For example, machine learning algorithms are a hot topic at the company as they are implementing hardware in their latest products that will help lead them into the AI future.

Blueprint Lab is a forward-thinking, tech-savvy company operating with more than 20 creative engineers who love what they do. Paul admits that he’d like to see more women engineers applying at the company. “It would be great to see more female mechatronic engineers in Australia,” he said. “We are always looking for dynamic people and there are simply not enough female graduates for the robotic industry right now.”

It’s amazing what can be done when you put together the right engineers and the right products. Blueprint Lab has made it their mission to incorporate precision components such as maxon motors in their products. With the growth in remotely operating vehicles of all kinds that are using robotic arms and grippers, there will be a place for companies like Blueprint Lab for years to come.

maxon motor Australia tel. +61 2 9457 7477.

maxon reports a steady result for 2020.

Sachseln, Switzerland – The maxon Group based in Sachseln, Switzerland, succeeded in largely keeping its revenue stable in the demanding 2020 financial year, in spite of the difficult market conditions caused by the COVID-19 situation.

The revenue amounted to CHF 553.5 million, compared to CHF 567.8 million in the previous year. There were some revenue losses in the automotive and aviation sectors, however, maxon was able to largely compensate this with the huge demand for drives for precise laboratory automation and ventilators in the fight against the coronavirus. This quick pivot required a high degree of flexibility and pragmatism from the management and employees. Undeterred by all the crises of 2020, maxon invested CHF 50.3 million in new factories, machines and systems. The cash flow amounted to CHF 37.1 million, compared to CHF 44.9 million in the previous year. Worldwide, the maxon Group has 3,059 employees at nine production sites.

“2020 was a rollercoaster ride like none we experienced before,” said Karl-Walter Braun, majority shareholder of the maxon Group. “In fact, it is our global presence and our international customers that are active in a wide range of markets and applications that enabled us to weather the pandemic.” Even during the shutdown, maxon managed to uphold the global supply chains. “This once again demonstrates the resilience of well-networked global value chains and a broad range of diversified contacts all over the world,” said Karl-Walter Braun.

The research & development (R&D) and sales departments in particular faced great challenges in the last year. “On the one hand, direct contact at the customer was impossible. On the other hand, direct contact with the suppliers, for detailed clarification of technical feasibility or delivery options, was difficult.” Around the world, maxon has some 330 employees in R&D and the company invests around CHF 35 million in this field.

Continued innovative strength

Even under the difficult conditions maxon faced, the company launched several new products in the field of precision drive technology. This includes micromotors for medical robots, but also multi-axis controllers for highly dynamic positioning tasks. A special highlight was the Mars expedition with the first excursions of the Perseverance rover, equipped with maxon BLDC motors, and the successful flights of the Ingenuity Mars helicopter, equipped with six maxon motors,” said Eugen Elmiger, CEO of the maxon Group. “All expectations regarding the length, altitude and duration of its flights have already been met.”

And down here on Earth, maxon exhibits continued innovative strength. For example, in the medical field, the company and one of its customers cooperated to develop a minimally invasive aorta pump, which helps cardiac patients to heal quickly. And in intralogistics, intelligent motion control solutions for AGVs (automated guided vehicles) are increasingly being used. In the past few months, the drive specialist also developed an innovation in the field of e-mobility: this summer, maxon presents the BIKEDRIVE Air, an light and invisible e-bike system that consists of mid-mounted motor, integrated battery and control element. It weighs only 3.5 kg and can be incorporated into elegant frames by bicycle manufacturers. The e-bike system will be available exclusively to bicycle manufacturers worldwide.

Looking ahead with confidence

maxon is satisfied with the current financial year. “Due to high-volume orders, the suppliers reached their capacity limits,” explained Eugen Elmiger. “The result is that we are experiencing supply shortages.” In the future, the company will continue its development as system supplier. “The customers should be able to get everything drive-related that they need for their products from a single source. This includes motors, gearheads, electronics, motor controllers and plugin solutions,” said Eugen Elmiger. “Additionally, we are pulling out all the stops to become the digital leader in drive technology.”

maxon motor Australia tel. +61 2 9457 7477.

DC motors from maxon take surveillance to the next level.

A revolution in concealed threat detection – making the world a safer place.

Radio Physics Solutions (RPS) is a small technology company based on the outskirts of Cambridge in the UK. This small, modest company works on leading-edge surveillance technology and has won several awards.

Threat detection at public venues is a serious issue. Current technology methods rely on scanners screening individuals in high traffic areas and shepherded in sections. This requires people to physically walk through scanning areas, in turn creating bottlenecks. RPS launched its latest fully automated product, Optracon™, which uses multiple sensors mounted remotely, to detect concealed mass casualty threats, hidden weapons, explosives and other dangerous objects, at distances of up to 30m. A true sensor fusion solution, Optracon™ collects data from radar, video analytics, LiDAR, machine learning algorithms, and artificial intelligence to provide a digital understanding of how people group and flow. The technology is small and automatically scans uncontrolled crowded public spaces beyond just an area or building. With an extended perimeter, responders have more time to act.

DC motors from maxon supported RPS to take surveillance to the next level. The motor housing in Optracon™ is custom made to the technology. A brushless maxon EC frameless 45mm flat DC motor drives the barrel and the shaft connected to a mirror. A brushless EC 32mm flat DC motor with hall sensors rotates the mirror. The barrel creates the essential scanning pattern. The mirror moves in a spiralling motion with varying diameter, and the frameless DC motor allows the mechanism to move this way without needing a personalised product.

David Leonard, head of engineering at Radio Physics Solutions, said “maxon was the only supplier offering frameless DC motors in such a convenient way, where a small company like ours, who are really designing from the ground up, can engage directly with the manufacturer. This is invaluable. maxon products come supplied with all required documentation, which is exceptional. You get excellent technical support on the assembly, even sharing the pitfalls. maxon really wanted to make sure we had the right product to achieve what we wanted to achieve. This outstanding customer support, coupled with the performance and accuracy of the product, is exactly what we at Radio Physics were looking for.”

The Optracon™ technology is unique to security screening infrastructure and represents a paradigm shift in understanding and responding to concealed threat detection.

Radio Physics Solutions have numerous deployments globally, for applications such as border control and security at governmental and royal facilities.

For more information please call maxon motor Australia tel. +61 2 9457 7477.

maxon Partners with Open-Source Champion Auterion to offer avionics that can change the industry.

DC motor specialist maxon – whose precision electric DC motors are aiding the autonomous helicopter Ingenuity and rover Perseverance to explore Mars – announced a partnership with Auterion, the company building an open and software-defined future for enterprise drone fleets.

maxon and Auterion have partnered up to create the most advanced, open ecosystem of avionics and motor integration in the drone industry. This combination and interaction of propulsion systems and flight computer / auto pilot joins maxon’s best-in-class brushless DC motors and Auterion’s module Skynode.

The implementation uses open-source standardisation that’s critical for the drone industry’s next phase of enterprise scaling and smooth workflow management. Across every user, open ecosystem integrations support component upgrades and mixed portfolios of small, medium and heavy-lift drones, carrying a wide variety of specialised payloads or cargo. Delivering maximum energy efficiency, flexibility, safety and performance by pursuing an optimal systems interplay between maxon’s high-precision DC motors, electronic speed controllers (ESC) and matching propellers connected to the complete Auterion platform.

The partnership will leverage both companies’ know-how to make drone operation, development and fleet management easy at dramatically reduced costs. The companies will explore long-term opportunities around propulsion systems and autopilot communication, data sharing and real-time monitoring.

Companies are turning to western-made options that are well-known and reliable for their open-source needs. “The partnership between Auterion and maxon provides access to the very best drone technology that also addresses impending federal legislation in the United States,” said Kevin Sartori, co-founder of Auterion. “We’re seeing utility companies and others that specifically require drone service providers to offer systems compliant with regulatory executive action. Ultimately, our open-source, software-defined ecosystem – built with outstanding partners like maxon – is what will instill greater trust in drone components and autonomous technologies.”

Eugen Elmiger, CEO of maxon Group, said, “With our motors in NASA’s Ingenuity helicopter, we flew on Mars. Now we are focusing on drones on Earth, which will play an important role in the automated future. I am very pleased that we are entering into a cooperation with Auterion, sharing our knowledge and experience so that we can better serve customers in the dynamic drone market. Their expertise in drone software coupled with our 60 years of experience as a global motor and drive specialist will generate promising solutions for the future.”

With unique capabilities, unmatched expertise and a long, proven history of designing and developing high-precision electric DC motors and motion control modules, maxon is poised to make industry changing contributions to the drone market and the future of autonomous crafts.

Auterion’s expertise in developing complete drone software stacks comes from its unique experience building Pixhawk and shaping the PX4 autopilot software, which has become the most used open-source flight control system for autonomous aircraft in the world. Auterion’s Skynode, made in the U.S. and marking a next-generation advancement for the Pixhawk standard, supports all different types of airframes, versatile payloads controlled via an SDK, LTE cloud connectivity and advanced onboard computation and apps.

Sartori added, “This partnership marks a new phase in software-defined drones and open standardisation. Together with maxon, we’ll offer a complete set of components to build state-of-the-art drones that scale to meet enterprise needs.”

With proper integration, enhanced communication, easy-to-implement and high quality and safe products, drone development and fleet operation can be quicker, more efficient, economically viable and safer.

For more information visit: aerospace.maxongroup.com or click here

maxon motor Australia tel. +61 2 9457 7477.

Engineering DC motors for outer space.

Successful space missions require specialised equipment. Head of maxon Group’s SpaceLab, Robin Phillips spoke to Suzanne Deffree at Design News about how to get DC motors just right for space travel.

Designing space-ready DC motors is a meticulous and complex process. Engineers need to account for extreme temperature fluctuations that persist for days at a time while operating during drastic changes in atmospheric conditions, where rotor blades cut through significantly fewer air molecules than in Earth’s atmosphere, simply to maintain flight. Every component needs to accomplish numerous mission-critical tasks while also withstanding the harshest of conditions. A very high priority is placed on the DC motors and drives within the equipment.

maxon Group has more than 100 motors on Mars currently and over 20 years of experience working on successful missions to the Red Planet. Most recently, NASA launched the Ingenuity Mars Helicopter, which successfully took flight on April 16, hosting six specialised brushed DC motors from maxon.

On June 15 Robin Philips will be speaking at the event Virtual Engineering Days, a three-day online event for the global manufacturing community that looks at critical issues and trends affecting today’s engineers. Robin will address how to design reliable DC motors and drives that offer greater precision while operating in demanding and harsh environments.

Suzanne Deffree at Design News spoke with Phillips, who shared a sneak peek into what attendees can look forward to learning about during his talk.

As the head of the SpaceLab at maxon, you are heavily involved in projects that demand heavy modifications for use in space. Could you walk us through your role and how maxon is driving innovation in space exploration?

Robon Phillips: My role is to use the experience I have gathered over the years from previous projects and my general observations of how the space industry is evolving, defining the kinds of products we offer as solutions for our customers. This involves both the development of new or modified motor and gearbox designs as well as the processes needed to build them. I ensure all the SpaceLab products are designed to a similar standard and that the build quality matches our customers’ expectations. I think maxon’s most significant contribution to innovation in the space industry is our catalogue of “COTS space products.” For these, we have taken custom designs that we have developed for space agency applications (ESA, JPL, etc.) and then removed some of the customization, but retained the core modifications that enabled the designs to be qualified for the extreme environmental conditions and are now offering these at reasonable prices as catalogue products to the rest of the space industry.

Recently, NASA sent a maxon drive system to space. What are the no-fail design requirements necessary for motors to properly function during the brutal lift-off conditions and the six-month-long journey through space?

Phillips: The requirements can be classified into two groups: 1) Environmental compatibility, which includes things like vibration and shock resistance for rocket launches but also, and more difficult to achieve, compatibility with the wide temperature ranges due to diurnal (day/night) cycling 2) quality requirements on all the production processes (both for our suppliers and us) that are needed to ensure to the maximum extent possible that the motors are correctly built.

What are the primary challenges design engineers face in this highly complex and mission-critical industry, and what approaches does maxon take to overcome them?

Phillips: One of the biggest challenges is changing the mindset of the engineers designing these products. Most of the time, they will be working on industrial products where the aim is high quality but strongly emphasizes cost-efficient solutions since we are constantly under pressure to have the lowest possible sales prices. For space applications, since we are just a component supplier, the cost of our product is secondary as it is only a tiny fraction of the overall spacecraft cost. This means that things like the mass and dimensions and requirements for absolute reliability are much more important than the cost. This often leads to completely different design solutions – e.g. For an industrial solution, we might have two separate, easily producible components made out of different materials, which we then glue together.

For the space solution, we would worry about differential expansions of the differing materials and the reliability of the glued connection. This would lead us to design a single-piece part, which is much more expensive due to its complex shape. Getting the engineers to understand this difference and switch between the two mindsets depending on what project they are working on is the challenge. We generally tackle this by using the same design engineers or performing design reviews where an engineer with space product experience is involved.

You are a keynote speaker at the upcoming Virtual Engineering Days addressing “Motors in Space -To Mars and Beyond.” What are a few learnings attendees can expect to take away from your keynote address?

Phillips: I will be giving a review of the history of Mars exploration so that the context of motors and the rovers they propel can be understood. I will discuss some of the design issues that we face to explain why we can’t just use a standard industrial motor, then review how we use the experience gained in the Mars applications to develop lower-cost “space catalogue” motors for the wide variety of new space applications.

What excites you most about connecting with your community at the upcoming virtual event?

Phillips: As engineers, we are always most excited in learning about the applications our products are used in. I always say, somewhat “tongue in cheek,” that motors are boring: they are just a cylinder with a shaft that turns – it is the applications that make the work interesting. Of course, the internal details are interesting to those of us that work on them, but this is how we want the motors to remain for our customers: boring cylinders, but with a shaft that they can absolutely rely on to turn when they power the motor on!

maxon motor Australia tel. +61 2 9457 7477.