maxon motor Australia: now delivering DC servo motors weekly.

Maxon motor Australia will now receive a weekly shipment of DC servo motor customer orders to their Sydney office.

maxon motor Australia has responded to their customer demands and from August 3rd will move to a weekly factory shipment. A steady increase in customer orders of the DC servo motors and gearheads has prompted the shift. As maxon motor Australia approaches their 10 year anniversary, the success of the DC servo motor manufacturer has stemmed from the reliability and quality of their DC servo motors, prompt customer service & support and expansion into growing technological fields such as robotics, medical and aerospace applications.

Customers in Australia and New Zealand will benefit from a reliable and regular shipment pattern as well as faster response times on orders of DC servo motors, gearheads, sensors/ encoders and other accessories.

For further information please contact + 61 2 9457 7477.

Bringing two worlds together.

maxon DC motors bring together robotics engineering & art: Korean artist U-Ram Choe created a sculpture that appears to breathe all on its own.

A brushed maxon RE-max 17 motor and gearhead are the powerful yet smooth force behind the breathing motion of the kinetic sculpture the Custos Cavum. Created by U-Ram Choe, this piece has its own story that weaves along mythical worlds. The Custos Cavum is a guardian of holes between two different realms, opening the holes by gnawing at them with their large front teeth. The 90% reliability of the motors was key to bringing the sculpture to life. Being in constant use, the DC motors needed to be 100% trustworthy.

To see these mythical creatures spring to life watch the video here.

For more information on DC motors in robotics please contact maxon motor Australia on tel. +61 2 9457 7477.

The maxon RE-max 17 (diameter 17 mm) with its ironless winding combined with a gearhead is responsible for the gentle movements of the sculpture Custos Cavum. © maxon motor ag 2016

drive.tech: maxon motors’ new site for innovation.

Advancements in drive technology, news items, blogs and stories come together on the drive.tech website created by maxon motor.

The leading manufacturer of DC motors and drive systems has created a new site for technology enthusiasts. Regularly updated to include projects supported by maxon motor, the latest hi-tech trends, global and robotic inventions, advances in medical applications or MARS / Space expeditions. Experts from within maxon motor share their knowledge as well as application examples showcasing the abilities of maxon DC motor capabilities.

For more information visit drive.tech or call +61 2 9457 7477.

maxon DC motors in the ReWalk Exo-skeleton.

An Israeli company, ReWalk Robotics, have developed an Exo-skeleton specifically helping quadriplegic people to walk again.

In 2003, Andre van Rϋschen was involved in a car accident that left him a paraplegic. Fast forward to 2012, Andre applied to be a test person for ReWalk’s Exo-skeleton in their London training camp. Andre learned to stand, climb steps, run and turnaround – an incredible feat for someone who was told they’d be confined to a wheelchair for life.

The Exo-skeleton has a controller that looks like a wristwatch. It’s a mechatronic support and movement system that works via a shifting of weight. The motors perform the movement of the hips and knees and it is here that there are four maxon brushed DC motors and gearheads. The RE40 DC motors with a planetary gearhead are designed for up to five years of service or 1,000,000 steps. Made with ceramic components to extend the service life of the motors they had to be 100% reliable, low maintenance and powerful yet small. The ReWalk is not only giving Andre the ability to walk – he meets people at eye level again and has his independence back.

For more information on maxon DC motors in medical applications please call +61 2 9457 7477.

The Exo-skeleton controller (above) and frame (below) by ReWalk © 2016 maxon motor ag

Andre van Ruschen © 2016 maxon motor ag

maxon DC motors exploring ocean depths up to 6,000m.

An ROV fitted with maxon DC motors found the largest submarine built in WWII, lying 190 metres below the ocean. The DC motors and drives have the ability to reach depths up to 6,000m.

A powerful maxon DC motor and planetary gearhead fitted with ceramic components, was the driving system behind an ROV that found the I-402 Japanese Submarine, destroyed by US forces at the end of WWII. Fitted with sonar, depth gauge, scanner, high-res camera and powerful LED lights the ROV is controlled by an operator using a compass and real-time video stream. The maxon DC drives are also fitted to the underwater gripper and camera adjustment mechanism.

The motors and gearheads were selected for their high power, small size, low noise and ability to withstand vibrations to prevent the seals failing when underwater. The DC motors ability to reach depths of up to 6,000 metres was crucial in determining appropriate drive systems for the ROVs. Re-discovered in mid-2015, the submarine was able to be identified thanks to the ROVs powerful lights illuminating its unique features.

For more information on ROVs or motor drive systems for underwater exploration please call maxon motor Australia Tel +61 2 9457 7477.

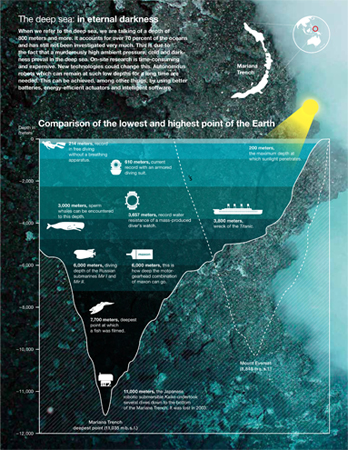

Above: comparison of the highest & lowest points on Earth. Below: The Seamor ROV © 2016 maxon motor ag

DC motors for moving sculptures.

A German artist has created animal sculptures up to 2.5m long using maxon DC motors and recycled bike parts.

With the ability to walk and turn their mechanical heads from side-to-side the pack move slowly visiting festivals all over Europe. Three powerful maxon DC motors and gearheads make this possible.

The drives are incorporated into the sculpture seamlessly, so much so, that the DC motors are virtually unseen. There are a number of motor-gearhead combinations, all of them robust and small in size. The drives have maxon motors special ironless winding with 90% energy efficiency and powerful torque to drive the sculptures forward.

For more information on DC motors please contact maxon motor Australia tel. +61 2 9457 7477.

Below: the maxon A-max 22 motor and maxon GP42 gearhead are some of the motors and gearheads used in the mechanical sculptures. © 2016 maxon motor ag