DC motors on the trail of wild animals.

maxon DC motors are used in a digital camera specially designed for making documentaries capturing herds of lions, elephants or wild antelope.

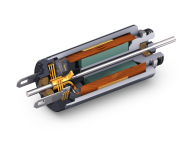

Documentaries are large productions utilising as small a team as possible. The ARRI AMIRA has been especially designed for single operator use. What sets this camera apart is the DC motors made by maxon inside, that ensure there are no chromatic aberrations (or “color fringing”) in the recordings. maxon RE8 motors with MR encoder and GP8 A planetary gearhead were specifically selected because of the small size and compact drive unit that fits within the camera casing. The brushed DC motors drive spindles in the sensor assembly that moves the filter into place in front of the image sensor and back again.

For further information please contact a sales engineer on tel. + 61 2 9457 7477.

maxon RE 8 motor

maxon GP 8A Planetary Gearhead

maxon MR encoder

The bionic model.

Rebekah Marine walked the runway at New York Fashion Week. What’s so inspiring is that Rebekah was the first to do so wearing her prosthetic i-limb.

It’s not every day you see a model with a bionic arm sashay down the runway at New York Fashion Week. But that’s exactly what Rebekah Marine, 28, did. Born without a right forearm she has refused to let this hold her back. Challenging stereotypes and proudly wearing her prosthetic, the i-limb quantum, Rebekah also publicly appeals for more tolerance in the modelling industry.

The groundbreaking limb was made by British Manufacturer Touch Bionics. The strong, powerful yet smooth movements in the prosthetic feature maxon DC motors and planetary gearheads. It is the first and only upper-limb prosthesis that enables the user to change grips by performing a simple gesture. This control is automated and allows for the change between the grip by moving the i-limb quantum in one of 4 pre-programmed directions.

For more information please contact Tel. + 61 2 9457 7477.

The I-limb quantum, by Touch Bionics.

Married by a robot.

A robot as a wedding clerk is the latest example of robots featuring in our lives in an extraordinary way.

China – in the land of smiles, a young couple have been married by a humanoid robot. RoboThespian stands behind the couple and speaking in his computerised voice, officiates the wedding ceremony. After the couple have said “I do”, he hands the rings to the bride and groom. The RoboThespian is a humanoid machine who can talk, dance, sing, present, act and even imitate emotions.

British company Engineered Arts have developed this life-sized robot so much so, that it moves about in a manner very similar to that of a human. These movements are made possible by an intelligent combination of “muscles” powered by the compressed air and maxon motors. In the hands, arms and torso, a mixture of A-max high performance motors and RE-max motors with neodymium magnets and planetary gearheads from maxon motor are used. Most importantly, the motors needed to be quiet and operate with precision to allow the smooth function of the RoboThespian. We think it’s a match made in heaven. And, the Happy Couple too of course!

For more information please contact Tel. +61 2 9457 7477.

Pictured below and featured in the RoboThespian is the A-max (left) and

RE-max (right) motors © 2015 maxon motor

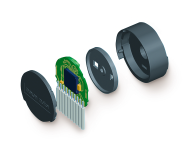

EPOS4 modules 50/15 and 50/8.

New product from maxon motor: concentrated motion, control power.

With the EPOS4, maxon motor is launching the next generation of the successful EPOS product range. The proven concept of the CANopen position controllers will now feature new functionality and improved control performance. A modular expansion project will also enable connection to various fieldbus interfaces and feedback providers. The first product in the range will be the high performance EPOS4 module with detachable pin headers in two power variants. Both modules have a particularly impressive power density: up to 1500 watt peak power at dimensions of just 57×62 millimeters. They are for both the control of brushed and brushless DC motors.

For more information please contact a sales engineer on Tel. +61 2 9457 7477.

DC motors in water.

maxon DC motors completely immersed in oil and submerged in water. An interesting look at complete device assemblies.

Synonymous with quality maxon DC motors are often selected for complex systems. The quality of maxon motors manufacturing is now more and more frequently called upon to develop the customers complete assembly. A case in point comes across the globe from as far as Abu Dhabi where dramatic effects are achieved by robotic motorised fountains surrounding luxury hotels and public areas. Often shooting over 40 meters in the air and synchronised not only with each other but also to music, the seemingly basic concept of a water fountain all of a sudden has become a complex DC motor driven multi axis automation application operating in an extremely difficult environment. maxon motors expertise has been called upon not only to develop a DC motor for use in water but to develop the entire fountain systems. From machining the high chromium content stainless steel components, encasing and sealing the motor and planetary gearheads in oil and developing the motion control electronics that provide the spectacular effects, maxon provides their customer with a complete manufacturing solution.

For the complete article contact maxon motor Australia for a copy of the latest Driven magazine.

Ph. +61 2 9457 7477.

Pictured below the brushless flat motor with hall sensor, Ø45 mm used in water © maxon motor

How many DC motors can be found in Romeo?

Win a Sphero Ollie by answering this quiz question in maxon motor’s drive magazine.

Tough and Smart, the Sphero Ollie is a water resistant, shock proof, app driven robot that delivers extreme fun. Reaching 22.5kph Ollie can do hundreds of tricks and at up to 30m away via a Bluetooth connection. maxon motor is giving away 3 of these robots and all you have to do is read the latest edition of maxon motor’s driven magazine. Not that this is a chore! The latest edition features articles from all over the world that exhibit the latest robotics and automation technologies. Dr Urs Kafader tutors us on controlling multiple motor axis in robotics covering both the mechanical aspects and motor control. The maxon motor magazine for tablet format contains interactive multimedia features and can be found on the Apple App Store and Google Play.

For more information please contact a sales engineer Tel. +61 2 9457 7477.

Sphero Ollie.

A complete system for powering your bike. Introducing the Bikedrive.

A compact and powerful hub motor from maxon motor is the first of its kind in the electronic bike market. Not just a motor combination, this is a complete three-part system.

Released in May 2015, the Bikedrive was designed and engineered by maxon motor with the assistance of Albert Iten, a Swiss former downhill world champion. The Bikedrive sits in the rear hub of a bicycle and is completely waterproof. It has ironless winding allowing the motor to achieve an efficiency of up to 90%. This is important in terms of battery consumption and energy recovery. The hub of the motor contains integrated electronics, sensors, gearhead and cabling all while fulfilling the need to be compact and able to integrate with the existing bike structure.

The complete system comprising of motor, battery and throttle grip (or Powergrip) took just under two years to develop. The motor itself weighs in at 3.5kg with maximum torque of 50Nm and efficiency up to 90%. The battery is 2.8kg and takes two hours to charge. The throttle grip has three gear-stages plus Turbo Boost and temperature monitoring on a compact LED information screen.

For more information please contact maxon motor Australia on Tel. +61 2 9457 7477.

The Bikedrive © 2015 maxon motor

Maxon brushless DC motors setting speed records.

Reaching speeds of up to 46 km/h, the fastest in the world for a Robot of its type, the Raptor robot is equipped with a maxon brushless DC motor in each of its two legs.

Developed by researchers in South Korea, the Raptor was engineered on a model of the Velociraptor Dinosaur. Weighing a total of 3kgs and 50 centimeters in height, the Raptor is powered by a maxon drive system consisting of a high-performance EC-4 pole brushless DC motor. Fitted with a planetary gearhead GP 32 HP and an MR Encoder, all controlled by a maxon ESCON module 50/5.

The lightweight yet powerful drive system allows the Raptor to balance on its own and jump over obstacles reaching 10cm in height.

For more information on maxon brushless DC motors and robotic applications please contact a sales engineer on +61 2 9457 7477.

The EC4-pole 30 brushless DC motor and the Raptor Robot © 2015 maxon motor ag and KAIST

DC motor with encoder now has greater resolution.

maxon’s DC motor with kit encoder combination has become an industry standard because of its cost effectiveness, high signal quality and versatility. Known for many years as the HEDL 5540 – 500 count per turn, the range has just expanded with the new AEDL 5810 – 5000 count per turn encoders.

A large range of DC motors are already available with the AVAGO encoders, both brushed DC motors and brushless designed DC motors. This is known as the ‘maxon modular system’ That allows an engineer or product designer to build up motor, gearhead and encoder combinations specifically to suit the application requirements. The modular system now expands dramatically with 9 new encoder resolutions ranging from 1000 counts per turn through to 5000 counts per turn. The new encoder is still an optical design and can be fitted with any motor that was previously available with the 500 count per turn unit and it uses the same DIN 41651 connections. With a 5V supply the output signal meets EIA Standard RS 422 using an AM26C31QD driver and has a typical signal rise and fall of 10ns. The high resolution makes it suitable for motor positioning tasks and is particularly useful for higher power motors that will not work with magnetic based encoder technologies. Focusing initially on the maxon multi-pole brushless DC motors and the new DCX range of motors the new encoder will provide solutions for demanding application requirements.

Contact maxon motor Australia for assistance selecting a motor with encoder. Ph.+61 2 9457 7477.

New encoder for DC motors © 2015 maxon motor.

A new line of high speed brushless DC motors from maxon.

A new series of high-speed brushless DC motors with speeds up to 120,000rpm, sterilisable (up to 2,000 autoclaves), very quiet operation and omit next to no heat as they operate, makes these perfect for hand-held surgical tools and industrial spindles.

The brushless DC motors come in three sizes with diameters of 8mm, 16mm and 19mm. The drive systems can be configured online with the option of planetary gearheads and encoders. Select, for example, different shaft lengths, winding types or ball bearings. The processes are automated and delivery is dispatched within 11 working days.

In addition to these new brushless DC motors, maxon motor will expand upon the popular X drives range. In late 2016, the brushless ECX22 brushless DC motor will be added, along with two power stage options and the ability to be sterilised.

For further information please contact a sales engineer on +61 2 9457 7477.

The new range of high speed brushless DC motors © maxon motor