maxon Robotics feature: Part 3

Industrial Gripper Robots: the maxon motor solution.

Across the many and varied robotics applications be they surgical, UAV, humanoid, collaborative or industrial robots, maxon motor offers motor and drive solutions.

Part 3 of our 6 part series looks at Industrial gripper robots. The gripping action must impart a firm grip but not so firm that an object is crushed. The requirements for these robots is high and the motors and drives must meet these high-expectations and perform reliably every single time. Specifically, high power density to produce maximum torque with restricted space constraints and precise interaction between motors and encoders is critical.

The maxon motor solution

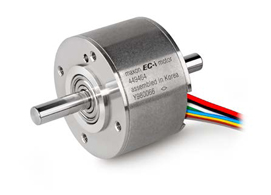

Maxon motors have a special winding that guarantee performance that is efficient and precise. The brushless DC motor with Hall sensors has a high overload capacity, small dynamic and a linear curve for maintaining control. The motor is highly dynamic and can be fitted with maxon gearheads to match.

Maxon brushless DC motor EC 13 with hall sensors © 2016 maxon motor

Other maxon solutions to consider

- Brushless flat DC motors: EC 9.2 flat or EC 20 flat.

- Planetary gearheads: GP 10A or GP 13A.

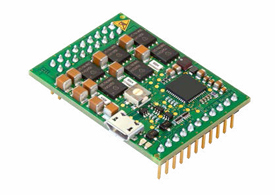

- Controllers: ESCON Module 24/2.

View the maxon EC flat program.

For more information on solutions to your motor and drive needs for robotics application please call maxon motor Australia on tel. +61 2 9457 7477.

Fitting the mould – Small DC motor customised for existing tool shape.

Old meets new with this customised small DC gear motor supplied by maxon motor Australia. Utilising the very latest motor technology on a gearhead profile that has been around for many years.

This small dc motor is a 12mm, 12V winding from the maxon DCX range. The DCX motors are the newest product range from maxon motor that feature very high power density and flexibility of supply with a large range of modifications possible. Normally a 12mm diameter motor would be fitted with a corresponding 12mm planetary gearhead that would match the applications required speed and torque levels. For this application the Australian customer had an exiting moulded part to suit a very old design 16mm gearhead. maxon motor Australia have worked extensively on the application requirements and have configured modern quality and performance into the old style gearhead shape. Custom motor and gearhead flanges were developed to maintain the profile of the old style whilst greatly improving the gearmotor output speed and torque. When developing modifications of this nature it is not satisfactory to simply change a dimension without fully understanding the consequences for the motor. Even something as simple as a an adaptor plate will need to have the applied forces modelled and evaluated before the design concept can be approved. This is a small step that helps define the quality of suppliers and their products.

Contact maxon motor Australia for information or assistance. Ph: +61 2 9457 7477.

Brushless DC motor with two gearheads.

maxon motor Australia delivered a company first. A right angle spiroid and planetary inline gearhead fitted either end of a brushless DC motor.

Demonstrating maxon motors Australia’s ability to customise motor and gearhead combinations to suit demanding applications, this combination represents a world first delivering calculated ratios for a specific X,Y movement.

Starting with the right angle gearhead. It is produced in the USA and has a high stiffness proportional to its compactness and low weight. Further specifications on the gearhead are: intermittent torque up to 9.4Nm, Helicon tooth form, 478N radial load and high quality combinations of needle and ball bearings.

Moving to the brushless DC motor which was manufactured in Switzerland and was selected because there was a requirement for zero shaft cogging (a motor without any mechanical detent), the 22mm brushless DC motor provides smooth controllable speed from very slow to a maximum of 18,000 rpm (restricted by gearhead input requirements). The Brushless DC motor delivers 25W at 12V. The motor has an all stainless steel construction and an internal hall sensor network for accurate speed regulation. On the rear side of the motor where normally you would see an encoder or another type of feedback device, a special mounting adaptor has been machined to fit a 22mm Ceramic Planetary gearhead from Germany. By adjusting the gearhead ratios it was possible to map the exact shape of an x,y scan and the number of motor revolutions determines the size.

Developed for use in a medical hand tool, the dual gearhead and motor combination has a low weight and can be precisely controlled. The highest quality has been achieved by maxon motor in Australia sourcing components from manufacturers in three countries, having then customised and assembled for the end user located in New Zealand. A truly global solution.

For further information or assistance please do not hesitate to contact maxon motor Australia.

Ph. +61 2 9457 7477.

New 80mm high performance 12V motor.

Available from maxon motor Australia is the new high performance 12V version of the 80mm KAG motor.

Kählig Antriebstechnik GMBH has extended the 80mm range of motors with an updated 12V version that delivers higher power. Previous performance levels were limited to 1800rpm with 700 mNm of torque. The new version of the motor can achieve 2800rpm at the same torque level. There are two different lengths available with corresponding power outputs enabling selection to suit application space and budget. The 80mm motor features two different mounting hole PCD options to suit various international norms, a common 12mm diameter shaft and can be assembled with the users choice of gearhead, encoder and brake. Simple 2-wire connection and robust construction with German made quality at low costs make this motor suitable for manufacturing machinery, processing applications and door actuations.

Contact maxon motor Australia for detailed information and 3D models.

Ph: + 61 2 9457 7477.

maxon motor Australia announce the release of two new motors to their range.

A new range of DC motors in 50mm diameter with power, length and voltage options. Produced by high quality manufacturer KAG.

The M50x28/I and M50x65/I. Fit between the existing M48 and M63 range offering more accurate motor size selection for various applications be they in the robotic, process control, manufacturing, food equipment, scientific instrumentation or communication industry. The new 50mm x28 DC motor produces 7% more power compared to the 48mm and equals the power of a 63×40 version. The motor DC voltage range spans 5V through to 42V DC and the two motor body lengths are 91 and 126mm. It can be supplied with an optical encoder and gearhead to suit the application requirements. The configuration choices include Planetary, Spur and Worm gearhead styles and safety holding brakes. Nominal speeds near 2800rpm and efficiencies of over 80% have been measured. Data sheets and 3D models are available online.

Contact maxon motor Australia for help selecting DC motors. Ph:+ 61 2 9457 7477.

maxon Robotics feature: Part 2

Humanoid Robots: the maxon motor solution.

In Part 2 of our 6 part series, we take a closer look at Humanoid Robots. Across the many and varied robotics applications be they humanoid, surgical, UAV, collaborative or industrial robots, maxon motor offers motor and drive solutions.

These special type of robots are being developed in anticipation of assisting us in our every-day lives. Be it rescue robots, in service or caretaker roles or as teaching aids. The motor/ drive requirements need to be lightweight, compact and powerful.

The maxon motor solution

Maxon motor offer multi-pole brushless DC motors with excellent torque-to-size ratios. In particular the brushless EC-i 40 with EASY encoder offers over 10,000 hours of service life. This motor is high precision due to high resolution encoders of up to 1,024 pulses per turn. Also dust and oil resistant, which is particularly important in rescue robot applications.

Other maxon solutions to consider

- DC motors: the DC-max or DCX motors.

- Brushless EC motors: EC-i, EC flat or EC-4 pole motors.

- Planetary gearheads: GP High Power or GP.

- Controllers: EPOS2 24/5, EPOS2 Module 36/2, EPOS2 50/5.

For more information on solutions to your motor and drive needs for robotics application please call maxon motor Australia on tel. +61 2 9457 7477.

The brushless EC-i 40 motor and EASY encoder © 2016 maxon motor.

Main picture: Humanoid robots featuring maxon brushless EC-i 40 motors. © 2016 maxon motor.

maxon Robotics feature: Part 1

Collaborative Robotics: the maxon motor solution.

Across the many and varied robotics applications be they surgical, UAV, humanoid, collaborative or industrial robots, maxon motor Australia offers motor and drive solutions.

Known as Cobots, these robots work alongside humans. Built with a sense of “perception” by way of torque feedback, this means the Cobot can “detect” the proximity of other machines or humans and avoid collision. High torque motors are valuable in this situation to keep the gearhead units small.

The maxon motor solution

The brushless flat EC-90 maxon motor with integrated MILE encoder. With the exceptional power-to-size ratio the flat EC-90 brushless motor is:

- compact

- with a robust design

- dust and oil resistant; and

- has very high precision output due to the high-resolution encoders offering up to 6,400 pulses per turn.

The EC-90 flat brushless motor with integrated MILE encoder from maxon motor

Other solutions maxon motor Australia offers

Brushless EC motors: The EC-i flat or EC-4 pole or EC flat.

Planetary gearheads: GP High Power or GP.

Controllers: EPOS2 24/5, EPOS2 Module 36/2, EPOS2 50/5.

View the entire maxon EC motor program

For more information on solutions to your motor and drive needs for your robotics application please call maxon motor Australia on tel. +61 2 9457 7477.

© 2016 maxon motor